Restores medium stones and finishing stones

to their original capabilities,

allowing you to sharpen with

the finesse of a master craftsman.

SCROLL

DOWN

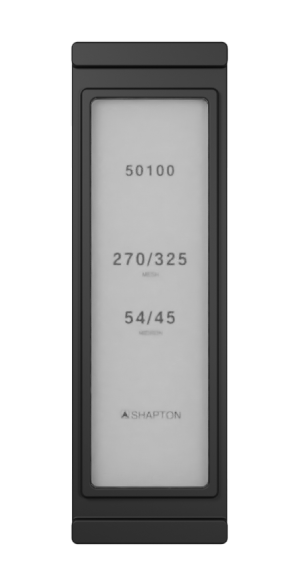

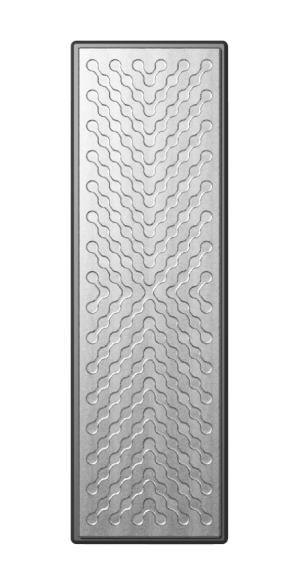

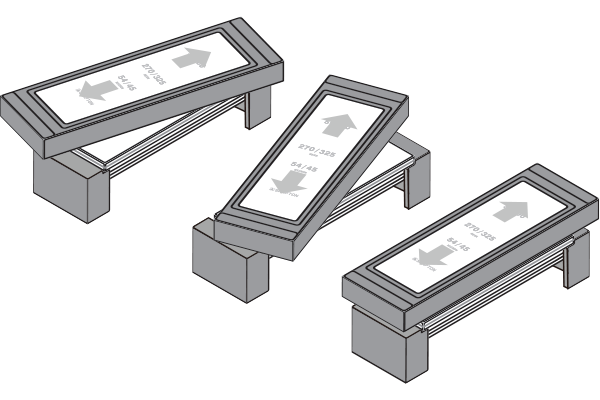

Glass-based lapping plate

High degree of surface flatness facilitates highly accurate lapping

Diamonds electrodeposited on the lapping face

Quickly bring your whetstone’s surface to optimum condition

Function

Function 1

Correct and flatten the whetstone surface

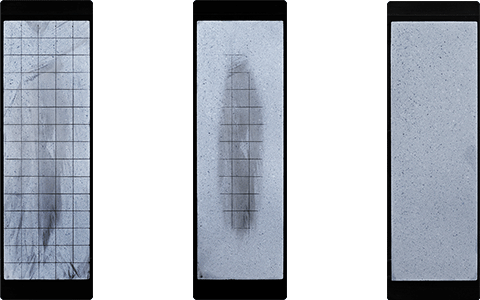

Each time a blade is sharpened, the whetstone surface loses some flatness.

The blade contacts the central area more frequently, meaning that it ends up somewhat concave.

Distortion of the whetstone surface is a cause of uneven sharpening, but can be corrected by using a Diamond Glass Lapping Plate to restore the flatness.

Function 2

Cure clogging

‘Clogging’ refers to swarf from blades or whetstone particles covering the abrasive protrusions on a stone’s surface.

Once a whetstone is clogged, blades lose contact with its surface protrusions and it becomes impossible to sharpen them.

Lapping the stone’s surface scrapes away the clogged parts and cures the problem.

Function 3

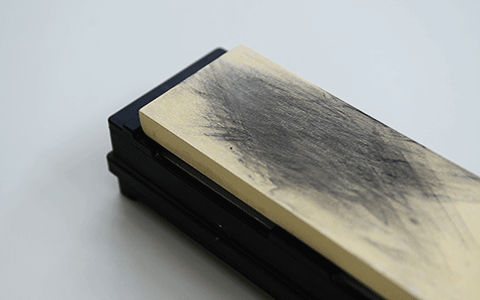

Even up surface roughness

Depending on what you use to correct a whetstone, the lapped areas may sometimes actually end up rougher.

Any scratches on the stone surface will affect the finish of your sharpened blade, and the finer the whetstone, the further it will deviate from its intended performance.

The Diamond Glass Lapping Plate allows you to even up the roughness across the whetstone’s surface, so both medium stones and finishing stones can be restored to their original

capabilities.

Spec

How to use

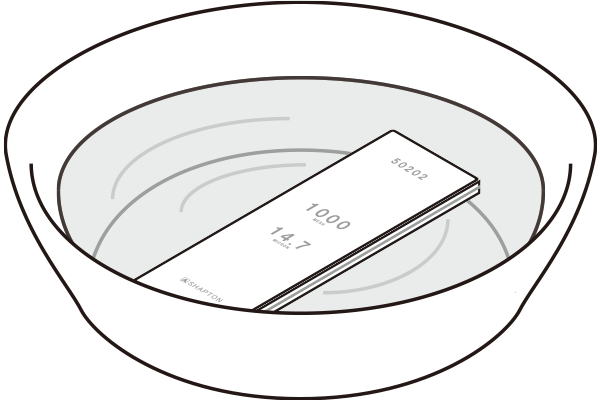

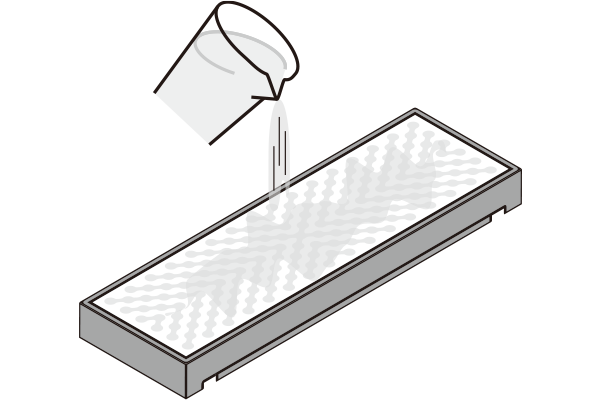

for 2 to 3 minutes before starting work on them.

When lapping non-Shapton stones,

you should ensure the stones absorb plenty of water first.

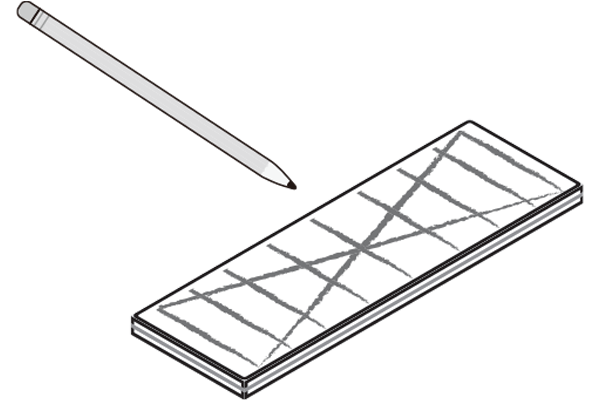

on the stone surface to be flattened.

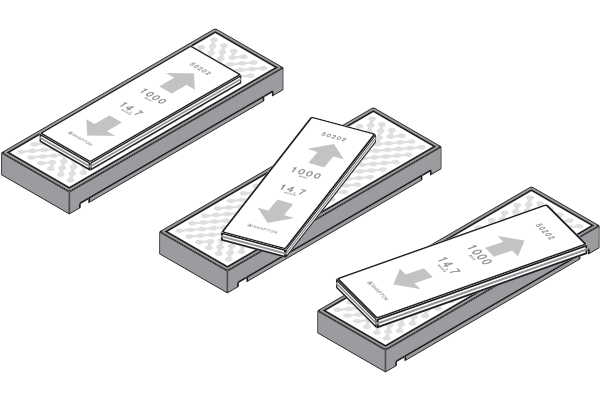

it forwards and backwards, then diagonally, using the whole surface evenly.

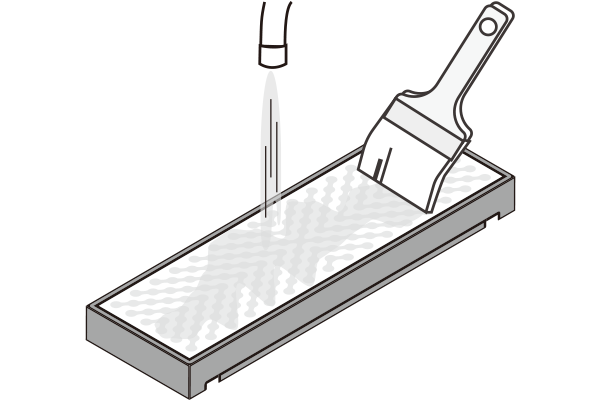

Any time slurry accumulates in the grooves,

rinse it off then resume lapping.

In this case, you should slide the lapping plate

forwards and backwards, then diagonally.

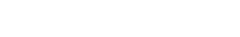

Parts where the lines get erased show where the lapping plate has made contact,

i.e. where flattening has been performed correctly.

rinse off any slurry promptly before putting the plate into storage.

We also recommend using a brush at this time.

FAQ

Keeping the sharpening surface in top condition helps maximize the sharpening stone's performance.

Parts where the lines get erased show where the lapping plate has made contact, i.e. where flattening has been performed correctly.

Boron-free plating processes are therefore more environmentally friendly.