空母 KUBO DIAMOND REFERENCE LAPPING PLATE

Facilitating flatness

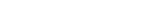

Blades are truly sharp when flat steel faces meet at an acute angle.

However, sharpening a blade starts a process of deformation in the stone,

and each time a blade is

sharpened, its own flatness gets progressively damaged.

Achieving true sharpness has traditionally required long years of experience,

and a huge investment of time and

effort.

The most important things are to create flat faces on the blades,

and to keep the sharpening stones flat in turn.

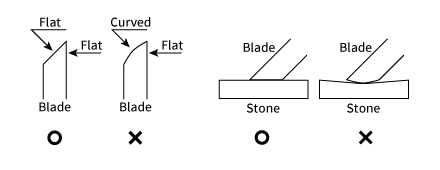

Using Shapton’s KUBO Diamond Reference

Lapping Plate together with

our sharpening stones can help you reach an unprecedented level of flatness.

The KUBO’s blade correction side helps you create blades that are

as flat as possible,

while the sharpening stone correction side keeps your stones flat too.

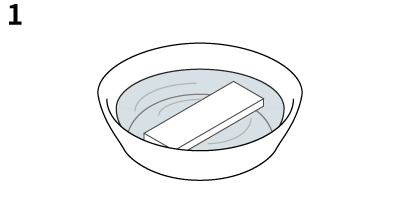

The stones you are intending to lap should be immersed in water for 2 to 3 minutes before starting work on them.

When lapping non-Shapton stones, you should ensure the

stones absorb plenty of water first.

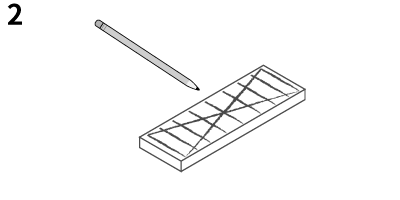

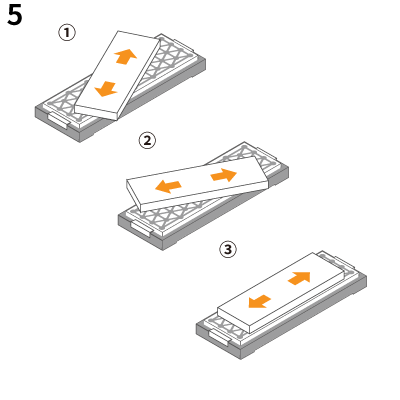

As a guide, use a pencil to draw a grid on the stone surface to be flattened.

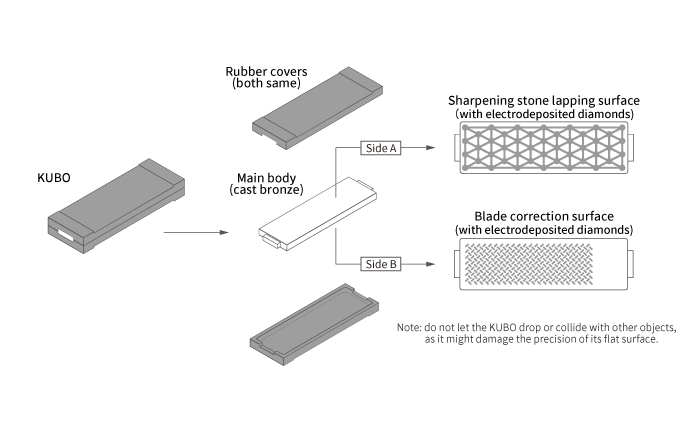

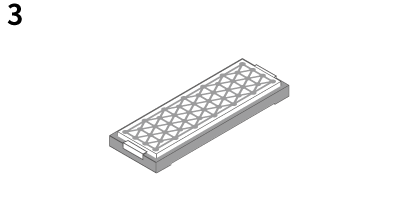

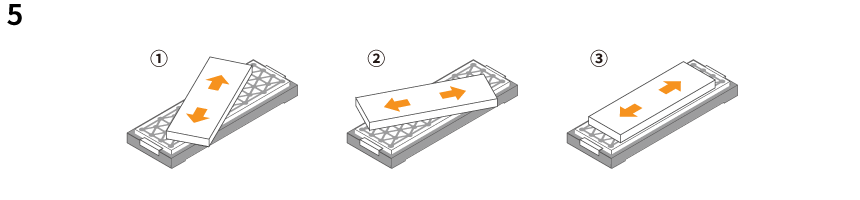

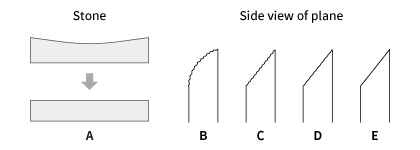

Place the KUBO somewhere stable, with the sharpening stone correction face (side A) on top.

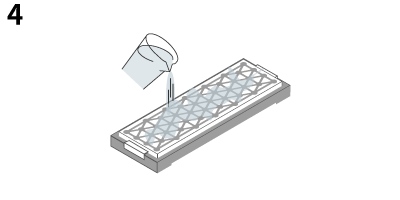

Splash on enough water to permeate the whole plate.

Ensure the stone to be lapped has absorbed plenty of water, then lay it on the sharpening stone correction face (side A),

and repeat the motion shown in steps ① and ② a

few times each.

Next, turn the sharpening stone around by 180 degrees and do the same again.

Once the sharpening stone is flat, finish it lightly as shown in step

③.

Parts where the lines get erased show where the sharpening stone correction face has made contact,

i.e. where flattening has been performed correctly.

When

complete, chamfer the stone’s edges.

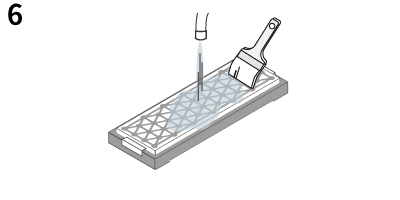

Once you have finished lapping, rinse off any slurry promptly before putting the KUBO into storage.

We also recommend using a brush at this time.

-

Note 1: If lapping more than one stone of differing grits, wash the plate clean before lapping each subsequent one.

Particular care is needed when lapping stones of less than 4 microns (4000 or above). -

Note 2: Lapping stones of 40 microns or above (320 or below) with the stone correction face (side A) is notrecommended,

as this would speed up abrasion/attrition of the diamonds.

Stones of 40 microns or above (320 or below) should be lapped by rubbing them against other stones.

-

■ Place the KUBO somewhere stable, with the blade correction face (side B) on top.

-

■ Use water throughout.

-

■ When correcting the blade, only exert force when pushing, move slowly so that the blade does not bend, and use the whole plate rather than sticking to one area.

-

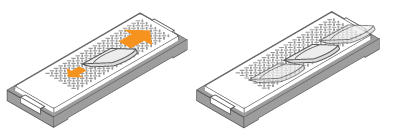

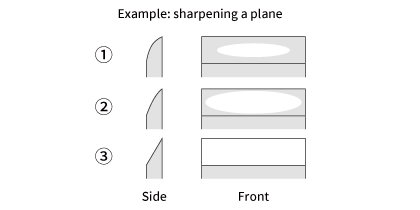

■ If the blade has lost its flatness, its central area will be scraped first.

This will look like an ellipse, as in step ①.

As correction progresses, the ellipse will gradually extend as shown in step ②.

As it finally becomes flat, it will appear as in step ③.

-

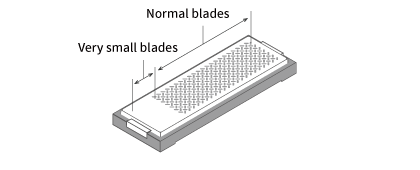

■ Very small blades or blades with sharp tips should be corrected using the unpatterned part.

-

Note 1: The blade correction face (side B) is not suitable for correcting nicked blades.

To correct a nicked blade, first work on it with a sharpening stone of 40 microns or above (320 or below). -

Note 2: The blade correction face (side B) is kept to a very high degree of flatness in order to create flat faces on blades.

If ever used for coarse sharpening, this would speed up abrasion/attrition of the diamonds and soon render it unusable.

That is why the blade correction face (side B) should only ever be used for correcting the flatness of blades. - Note 3: Take care not to scratch the blade correction face (side B) with the edges of blades or anything similar, as there is a risk of the diamond surface being gouged.

The procedure changes depending on the initial state of the blade.

-

If the blade is dull

use steps ③④⑤

-

If the blade has lost its flat faces

use steps ②③④⑤

-

If the blade is nicked

use steps ①②③④⑤

- ① Work on the blade with a sharpening stone of 40 microns or above (320 or below) until any nicks have been removed(see B).

-

Stones of 40 microns or above (320 or below) should be used for removing blade nicks.

These coarser stones deform more quickly than finer stones of 30 microns or below (500 or above), and are unsuitable for creating flat surfaces as you sharpen the blade. - ② Correct and flatten the blade (see C).

- Use the blade correction face (side B).

- ③ Flatten (lap) the sharpening stone (see A).

- Use the sharpening stone correction face (side A).

- ④ Use 4 to 30 micron (500 to 3000) stones to sharpen the blade while maintaining its flatness (see D).

-

Once you have got flat surfaces, it is important to sharpen the blade using the whole surface of the stone, and not to spend too long on it.

If you spend too much time on this process, the sharpening stone will start to deform and eventually the blade itself will also deform. - ⑤ Use a stone of less than 4 microns (4000 or above) to finish the sharpening, while maintaining the blade' s flatness (see E).

-

Use the same approach as in step ④.

When you now finish sharpening the blade, retaining its flatness, the blade and stone will adhere to each other so that even if you take your hand off the blade, it will stay standing on the stone.

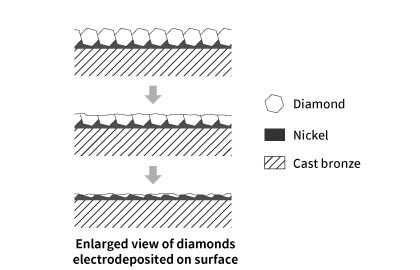

Long use of this product can lead to abrasion/attrition of the diamonds.

If the polishing ability declines, you can make use of our diamond re-electrodeposition service.

Diamond abrasion/attrition

Please contact us for details such as the cost, etc.

Inquiry Form

KUBO

- DIAMOND REFERENCE LAPPING PLATE

- K0799